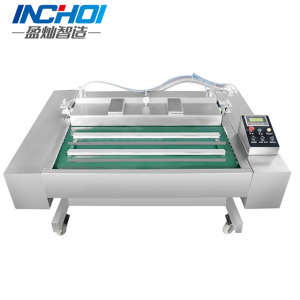

I-DLZ-420/520 Umshini wokupakisha oqhubekayo wekhompyutha oqhubekayo we-thermoforming vacuum

Ividiyo

Amapharamitha wezobuchwepheshe:

| Imodeli | Ububanzi befilimu obungaphezulu | Ngaphansiububanzi befilimu | I-vacuum degree | Umoya ocindezelwe | ukunikezwa kwamandla kagesi | amandla | Isisindo Esiphelele | Ubukhulu |

| I-DLZ-420 | 397 mm | 424 mm | ≤200pa | ≥0.6MPa | 380V50HZ | 14KW | 1800kg | 6600×1100×1960mm |

| I-DLZ-520 | 497 mm | 524 mm | ≤200pa | ≥0.6MPa | 380V50HZ | 16KW | 2100kg | 7600×1200×1960mm |

Imininingwane Yomkhiqizo:

1.Isistimu yokushayela

2.Ngaphansi kwefilimu idivayisi yokubeka i-pre-tensioning

3.Ukuphakamisa uhlelo

4.Cross cutter idivayisi

5.Servo uhlelo ikhodi

6.Upper Film ukwakha idivayisi

7.Ukugaywa kabusha kukadoti

8.Umdwebo womhlangano wekhabhinethi kagesi

Isicelo:

Imishini ifaneleka kakhulu:inyama yenyama,isoseji elosiwe,isoseji le-crispy,izinyawo zenkukhu ezifakwe emanzini anosawoti,amaqanda ezigwaca,i-tofu eyomisiwe,imikhiqizo yezinhlanzi,imikhiqizo yenyama yenkomo,imikhiqizo yewundlu,usoso wenhlabathi,izithelo ezomisiwe,ushizi,izinto zikagesi,imikhiqizo yensimbi. neminye imikhiqizo edinga ukupakishwa kwevacuum.

304 Isakhiwo sohlaka lwensimbi engagqwali

1. Isakhiwo sinamandla amakhulu nokumelana nokugqwala.Izimbobo zesikulufu endaweni ngayinye egxilile zicutshungulwa nge-laser enembe kakhulu ngesikhathi esisodwa ukuze kuqinisekiswe ukunemba kokuhlanganisa nokwenza wonke umshini usebenze kahle.

2. Ukunwetshwa okwengeziwe, lapho ifomu lokupakisha lidinga ukuthuthukiswa, izingxenye ezifanele zingengezwa nganoma yisiphi isikhathi ngokuvumelana nezidingo zokupakisha.

Idivayisi yokuphakamisa yokuxhumanisa ama-eksisi amane

1. Idivayisi yokuphakamisa yenziwe nge-6061 ye-aviation aluminium alloy, okwandisa ukuzinza namandla ezingxenye.Izingxenye ezishelelayo zisebenzisa ama-linear bearings aphezulu angenisiwe, anembe ngokuma futhi azinzile ekusebenzeni.Ukuphakama kokuphakamisa kungalungiswa ngokuzenzakalelayo ngokuya ngobukhulu bokupakishwa komkhiqizo.Ngaphandle kokushintsha isivinini sokugijima, ibanga lokuphakamisa liyafinyezwa ukuze kuthuthukiswe isivinini sokupakisha somshini wonke.

2. Izingxenye zihlotshiswe ngemikhono yethusi yegraphite ukuze kwandiswe ukuthambisa, ukunciphisa ukuhuzuka nokwelula impilo yesevisi.Ngaphezu kwalokho, umkhono wethusi we-graphite umelana kakhulu nokucindezela, okuqinisekisa ukuvalwa kwegumbi lokubumba kanye negumbi le-vacuum.

Idivayisi kagesi kazibuthe pre-iqina

1. Ngokusebenzisa ibhuleki lika-electromagnetic, ibhuleki lizinzile futhi amandla ayalingana, agwema isimo sokushwabana nokugoqa kwemikhiqizo epakishiwe.

2. Isibonisi sedijithali sibonisa ukuthi amandla okuqinisa ayalungiseka.Isihluthulelo singalungiswa ngokushelelayo futhi ngendlela enembile ngokusho kokuqina, ukuguquguquka nokuthambile kwefilimu yokupakisha ukuze kuzuzwe umphumela omuhle kakhulu wokupakisha.

Uhlelo lukagesi

1. Uhlelo lokulawula oluhlakaniphile lwamukela uhlobo lwe-Siemens yaseJalimane ngokufanayo, futhi amaphuzu okulawula ayasabela futhi ayabambisana.Izinga lokushisa, isikhathi, kanye nomfutho we-vacuum wengxenye ngayinye kuboniswa esikrinini sekhompyutha, futhi inomsebenzi wayo wokubona amaphutha.

2. Ukwamukela isiJalimane Siemens high inertia servo motor kanye nomshayeli, ukuma kweketango kunembile futhi kusebenza ngokushesha.

Isistimu yokusebenza ehlakaniphile

1. Ukusebenza kwesikrini sokuthinta, ukulawula uhlelo oluzenzakalelayo, ukuboniswa kwesithombe saso sonke isimo sokugijima, ukutholwa okuzenzakalelayo kwembangela yokwehluleka, ukusebenza okulula nokugcina okokusebenza.

2. Isikrini sokusebenza esihlakaniphile nesomuntu silula futhi sicace kakhudlwana.Ipharamitha ngayinye ingalungiswa ngokufanele ngokwemikhiqizo ehlukene, futhi imingcele yenqubo yomkhiqizo ehlukene ingagcinwa.Ukushaya ngokuchofoza kanye konga isikhathi nomzamo.

Uhlelo lokuvikela ukuphepha

1. Zonke izingxenye zokudlulisela;izingxenye ezinezinga lokushisa;izingxenye zokusika nezinyakazayo zifakwe izinto zokuvikela, futhi amaswishi okuxhumana kazibuthe afakiwe.Uma izisetshenziswa zokuvikela zingekho endaweni noma izisetshenziswa zangempela zokuvikela umshini zingekho, umshini uzoma ngokushesha.

2. Imishini ngokwayo ifakwe amaswishi okumisa izimo eziphuthumayo ezindaweni ezihlukene, ukuze kumiswe umshini ngesikhathi lapho kwenzeka ingozi.

3. Akuvunyelwe ukwelula izandla, izinyawo, izingalo nezinye izingxenye nge-switch ye-beam, uma sekuzwakele, izoma ngokushesha.

Isistimu yokugaya kabusha ifilimu

1. Ukugaywa kabusha kwemfucuza kunomshini wokubona ohlakaniphile, ongalungisa ngokuzenzakalelayo isivinini sokusebenza ngokuya ngobude befilimu yemfucuza.

2. Idivayisi ayinamsindo, kulula ukuyiqoqa ifilimu, ifakwe amandla angu-150W, ukusebenza okungaqondile, ukonga ukusetshenziswa kwamandla.

Ukwakha kanye nokushisa uphawu isikhunta

Zonke isikhunta singashintshwa ngokushesha, futhi amasethi amaningi esikhunta angashintshwa ngesethi yemishini ukuze kube lula ukupakishwa kwemikhiqizo eminingi.

Multifunctional slitting uhlelo

Ngokusho kwemikhiqizo ehlukene, ingakwazi ukubona ukusika ekhoneni eliyindilinga, ukudabula kalula, izimbobo ezilengayo, ukusika ama-serrated, ukubhoboza okugcwele kanye nezinye izinhlelo zokusebenza, futhi ijubane lokushintshwa komsiki liyashesha futhi kulula.

Ukucushwa okuningiliziwe:

1.Isilawuli sesiJalimane se-Siemens Computer Programmable Logic Controller (PLC), umthamo omkhulu wokufakwayo kanye nokuphumayo.

2. IsiJalimane Siemens 10-intshi umbala interface womuntu-umshini touch screen.

3. 1.5KW German Siemens servo system control, high-speed and high-nemba high-step-by-step isivinini.

4. I-TYC clamping chain

5. Izinto zikagesi ezingenisiwe (i-American Bonner color sensor, i-Schneider contactor & relay, inkinobho yokushintsha, isivikelo samandla, i-Yangming solid state relay, i-Japanese Omron switch proximity, njll.).

6. Ingxenye yomoya ithatha i-Yadeke Valve Terminal system pneumatic.

7. Iphampu enkulu yevacuum engangcolisi yomshini wokupakisha we-vacuum ophezulu we-vacuum ovumela imvelo (i-Rietschle/Busch, ozikhethela ngokwemfuneko yeklayenti) engeniswe isuka e-Germany nephakheji yoqobo, enezinga eliphezulu le-vacuum elingu-0.1 millibar.

8. Isistimu yokulandelela i-photoelectric kanye nefilimu yombala engenisiwe ingasetshenziswa ukuze kuqinisekiswe ukuthi indawo yephethini ilungile.

9. Wonke umshini wamukela uhlaka lwensimbi engagqwali engu-304, olunamandla amakhulu, ukumelana nokugqwala okuqinile futhi akulula ukukonakalisa.

10. Ulwelwesi olungaphezulu noluphansi luthatha uhlobo olusha lwesistimu ye-membrane edonsayo.

11. Ukubumba, ukufaka uphawu nokuphakamisa kusebenzisa i-pneumatic lever yokuzimela kanye nohlelo lokuzikhiya.

12. Ukuma ngokunemba ngaphambili, emuva, kwesokunxele nakwesokudla.

13. I-Transverse cutter isebenza ngokuzimela ngesisiki esisodwa kanye nesilawuli sekhompyutha esimaphakathi.

14. Ifakwe uhlelo lokugaywa kabusha kwemfucuza ekhoneni.

15. Ibhere eshelelayo ephakamisayo ithatha umkhono wethusi wegraphite ongagcotshisi.

16. Zonke izingxenye zokwakha, zokubeka uphawu, ummese ovundlile kanye nommese we-longitudinal zifakwe uhlelo lokuvikela ukuphepha kanye nesembozo sokuzivikela.

17. Izinto ezisetshenziswayo zifakwe izinhlelo ezethusayo noma zokuvikela ezifana nokulahlekelwa kwesigaba samandla noma ukuguqulwa, ugesi omningi noma ophansi, ukugcotshwa kwemishini ngezikhathi ezithile, njll., okulula ukuthi opharetha bawasebenzise futhi bawalungise.Ukuvikelwa kokumisa okuzenzakalelayo lapho kukhona ukwehluleka futhi kubonise imininingwane yephutha kanye nokwelashwa okuhambisanayo kokwehluleka kukhompyutha.